In the world of industrial valves, the debate over the most suitable control valve for various applications is always going on. And out of all the options, Crane Butterfly Valves stand out as the preferred choice of all. But when exactly can these valves be trusted to work well as control valves?

But before entering into those details, it’s important that we understand from the basics. Isn’t it?

Understanding Butterfly Valves

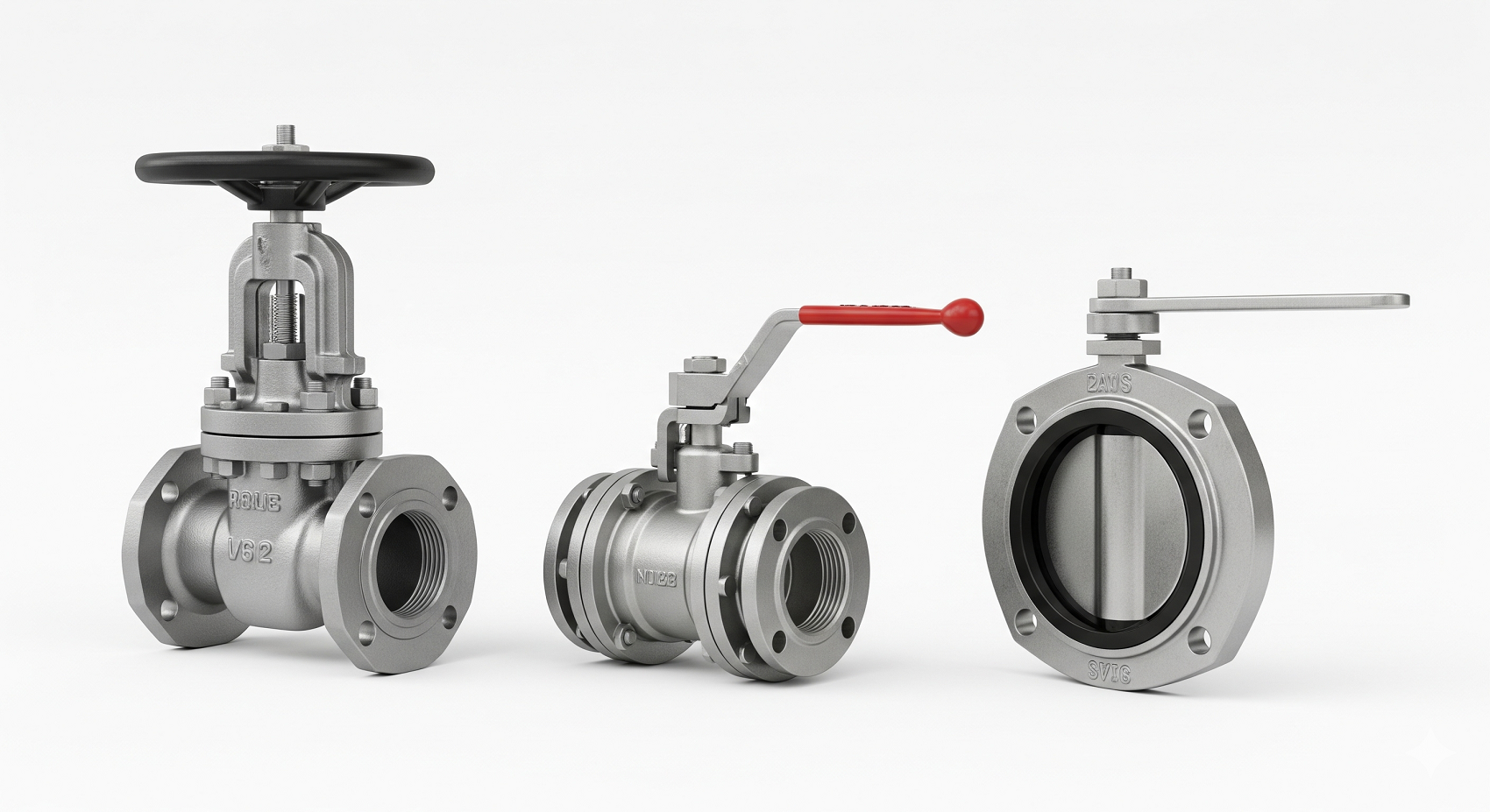

Think of a butterfly valve as a disk placed in the middle of a pipe. This disk can rotate around an axis running across the diameter of the pipe. When the valve is fully open, the disk is parallel to the flow, allowing for unrestricted passage of fluid. Similarly, when the valve is closed, the disk is perpendicular to the flow, blocking it completely.

Butterfly valves are well known for their design and fast functionality. This makes them widely loved in various industries. Specifically, crane Butterfly Valves are crafted to offer precision and durability guaranteeing performance in applications. Butterfly valves are commonly used in various industries as flow control devices, and they can indeed be employed as control valves in certain applications. Their design allows for streamlined flow control, making them well-suited for both on/off and throttling services.

Hope the basics are clear, now let’s explore more about these butterfly valves.

When Can Butterfly Valves Be Used As Control Valves?

we will explain to you using various scenarios.

Adaptable in Flow Regulation

Imagine that a water treatment facility needs to manage its varying flow rates to ensure efficient purification. Crane Butterfly Valves, with their ability to regulate flow seamlessly, become the go-to solution in such dynamic environments.

Crane Butterfly Valves are known and incredibly flexible for their large flow capacity/ flow regulation. This means they can handle a significant amount of fluid without causing excessive pressure drop. When dealing with large pipelines where high flow rates are common, butterfly valves can regulate the flow efficiently, making them ideal for applications where a range of flow rates is required, such as in water treatment plants or HVAC systems.

Cost-Effective Solutions

In situations where budget constraints are a concern, such as in small-scale manufacturing or local water distribution systems, Crane Butterfly Valves provide an economical yet efficient control valve solution.

One of the key advantages of Crane Butterfly Valves is their cost-effectiveness. Butterfly valves are generally more cost-effective compared to other types of control valves. Their simple design, combined with ease of maintenance, helps to reduce installation and operational costs. Therefore, this affordability makes them an attractive choice for applications where precise control is critical, and budget considerations are most important.

Quick Operation and Emergency Situations

Consider a scenario in a chemical processing plant where the need to stop a sudden leak arises. this is where the quick operation of Crane Butterfly Valves acts as an immediate response, reducing the potential hazards and ensuring the safety of the employees and equipment.

In certain applications, the speed of valve operation is important. Crane Butterfly valves can open and close relatively quickly. This fast operation is helpful in emergencies where quick action to changes in flow is necessary. For instance, in systems requiring swift shut-off or emergency isolation, butterfly valves can be really useful.

Minimal Space Requirements

Think about a scenario in a crowded utility room where traditional valves might find it difficult to fit. Crane Butterfly Valves not only fit easily into limited spaces but also give reliable control without giving up efficiency.

Space constraints can be a significant problem in many industrial sectors. Crane Butterfly Valves, known for their compact design, are good in situations where space is limited. In applications where the available installation space is restricted, these valves can be more practical than bulkier choices. their design allows for easy installation in tight spaces without compromising performance.

In simple terms, butterfly valves can be used as control valves in situations where their properties match the requirements of the application. Their cost-effectiveness, large flow capacity, quick operation, and suitability for certain industrial settings make them the best-loved choice for various scenarios.

However, it’s important to recognize their disadvantages, especially in applications demanding precise control. For processes where fine-tuned adjustments are critical, specialized control valves designed for accurate flow modulation may be more correct to use. The choice between butterfly valves and other control valve types eventually depends on the specific needs of the system, considering factors such as budget constraints, space limitations, and the nature of the fluid being handled.

For premium Crane Butterfly Valves and other industrial solutions, trust RZBM. Our commitment to quality and innovation ensures that your operations run smoothly. Visit our website today to explore our range of products and discover how RZBM can elevate your industrial experience.