You have a beautiful garden and have just invested in a top-notch irrigation system for your garden, or maybe you are upgrading your industrial piping system. Everything seems perfect until a valve gives out, causing a major disruption. This scenario is every homeowner’s and business owner’s nightmare. Luckily with Cepex valves, you can significantly reduce the risk of such mishaps. In this blog, we will dive into the world of Cepex Valves, their applications, advantages, and essential tips for installation and maintenance to keep your systems running smoothly.

UNDERSTANDING CEPEX VALVES

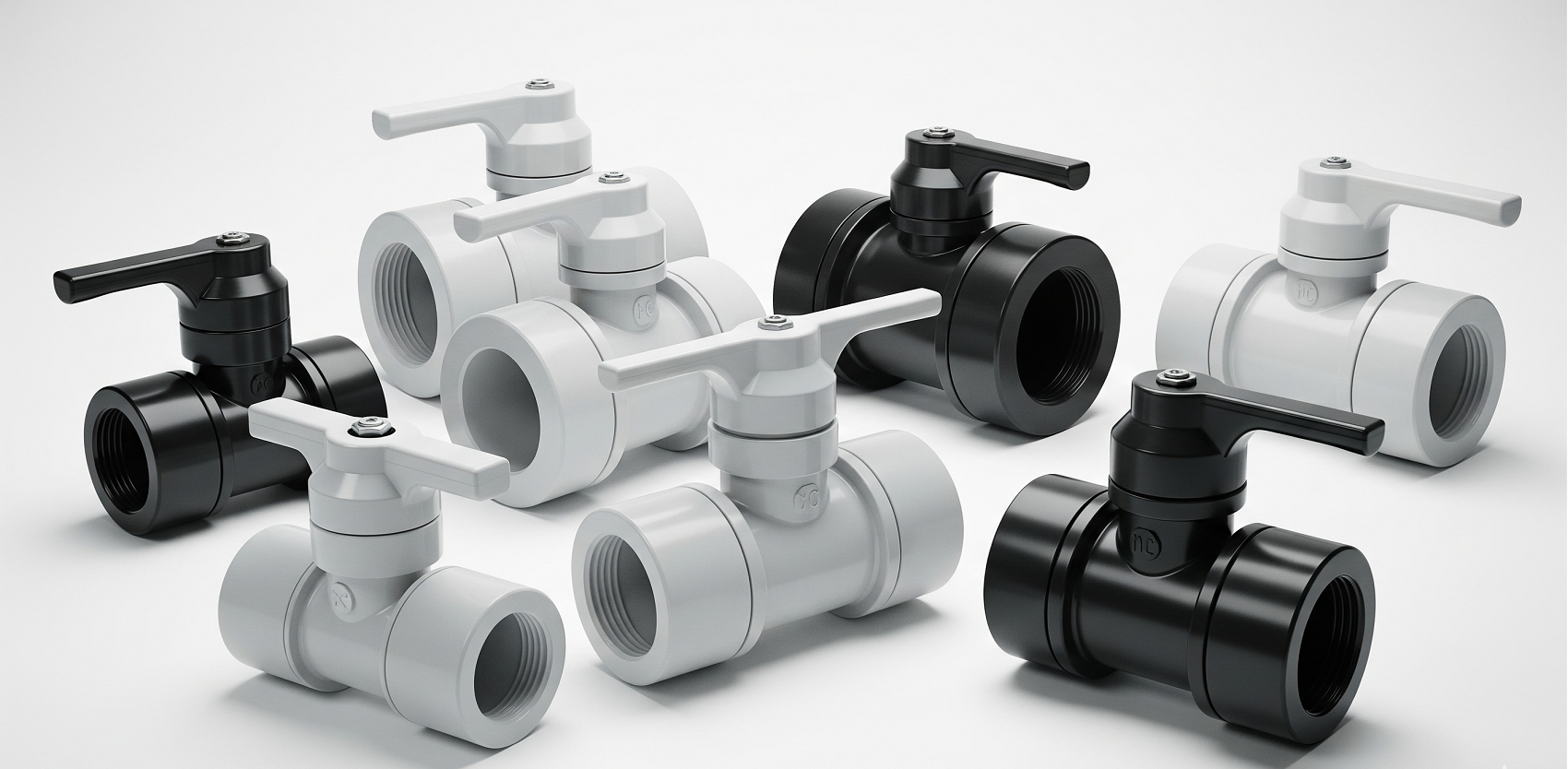

Cepex Valves are renowned in the industry for their durability, reliability, and performance. But what exactly are they? Cepex is a brand known for producing high-quality thermoplastic valves and fittings. These valves are designed to control the flow of various fluids in different systems, offering precise management and long-lasting service. From residential plumbing to industrial applications, Cepex Valves are versatile enough to meet a wide range of needs.

WHAT ARE THE APPLICATIONS OF CEPEX VALVES?

Cepex Valves are used in numerous applications across different sectors due to their robustness and adaptability. Here are some common uses :

Water treatment plants: Cepex Valves are ideal for controlling the flow of water and chemicals in treatment plants.

Irrigation systems: They make sure water distribution in agricultural and landscape irrigation systems.

Swimming pools: These valves help manage water circulation and treatment in pools.

Chemical processing: Their resistance to various chemicals makes them suitable for controlling flow in chemical processing plants.

HVAC systems: In heating, ventilation, and air conditioning systems, Cepex Valves regulate the flow of water and other fluids.

WHAT ARE THE ADVANTAGES OF CEPEX VALVES?

Choosing Cepex Valves comes with a multitude of benefits :

Durability: Made from high-quality thermoplastics, Cepex Valves are resistant to corrosion, chemicals, and extreme temperatures.

Reliability: They provide consistent performance, ensuring systems operate smoothly without frequent interruptions.

Ease of installation: Designed for user-friendliness, these valves can be installed with minimal hassle.

Versatility: With a range of models and sizes, Cepex Valves can be used in various applications, from residential plumbing to industrial systems.

Cost-effectiveness: Their long lifespan and low maintenance needs make Cepex Valves a cost-effective choice in the long run.

INSTALLATION AND MAINTENANCE TIPS FOR CEPEX VALVES

To get the most out of your Cepex Valves, proper installation and maintenance are crucial. Here are some tips to help you :

INSTALLATION TIPS

Correct sizing: Make sure that you select the right size of valve for your system. An improperly sized valve can cause inefficiencies and potential damage.

Proper Alignment: Align the valve correctly with the pipes. Misalignment can cause leaks and stress on the valve and piping system.

Clean Installation Area: Before installation, clean the pipes and the area around the valve. Dirt and debris can interfere with the valve’s operation and sealing.

Use appropriate tools: Always use the recommended tools for installation. Avoid using excessive force, as this can damage the valve.

Follow manufacturer guidelines: Adhere to the installation instructions provided by Cepex. These guidelines are tailored to ensure optimal performance and longevity of the valves.

MAINTENANCE TIPS

Regular Inspection: Periodically inspect the valves for any sign of wear, leaks, or damage. Early detection of issues can prevent problems.

Clean the valves: Over time, debris can accumulate and affect the valve’s operation. Regularly clean the valves to ensure they function smoothly.

Lubrication: Some Cepex valves may require lubrication to maintain their performance. Check the manufacturer’s recommendations for the type and frequency of lubrication needed.

Check for corrosion: Although Cepex Valves are resistant to corrosion, it’s still wetwise to check for any signs, especially if used in harsh environments.

Replace worn parts: If you notice any worn or damaged parts, replace them promptly to avoid compromising the valve’s integrity and performance.

Cepex valves are a smart investment for anyone looking to ensure efficient and reliable flow control in their systems. Whether for residential, commercial, or industrial use, these valves offer unmatched durability, ease of installation, and low maintenance needs. By following the installation and maintenance tips provided, you can maximize the lifespan and performance of your Cepex Valves, ensuring your systems run seamlessly.

Ready to enhance your system’s performance with Cepex Valves? Visit RZBM today to explore our extensive range of Cepex products