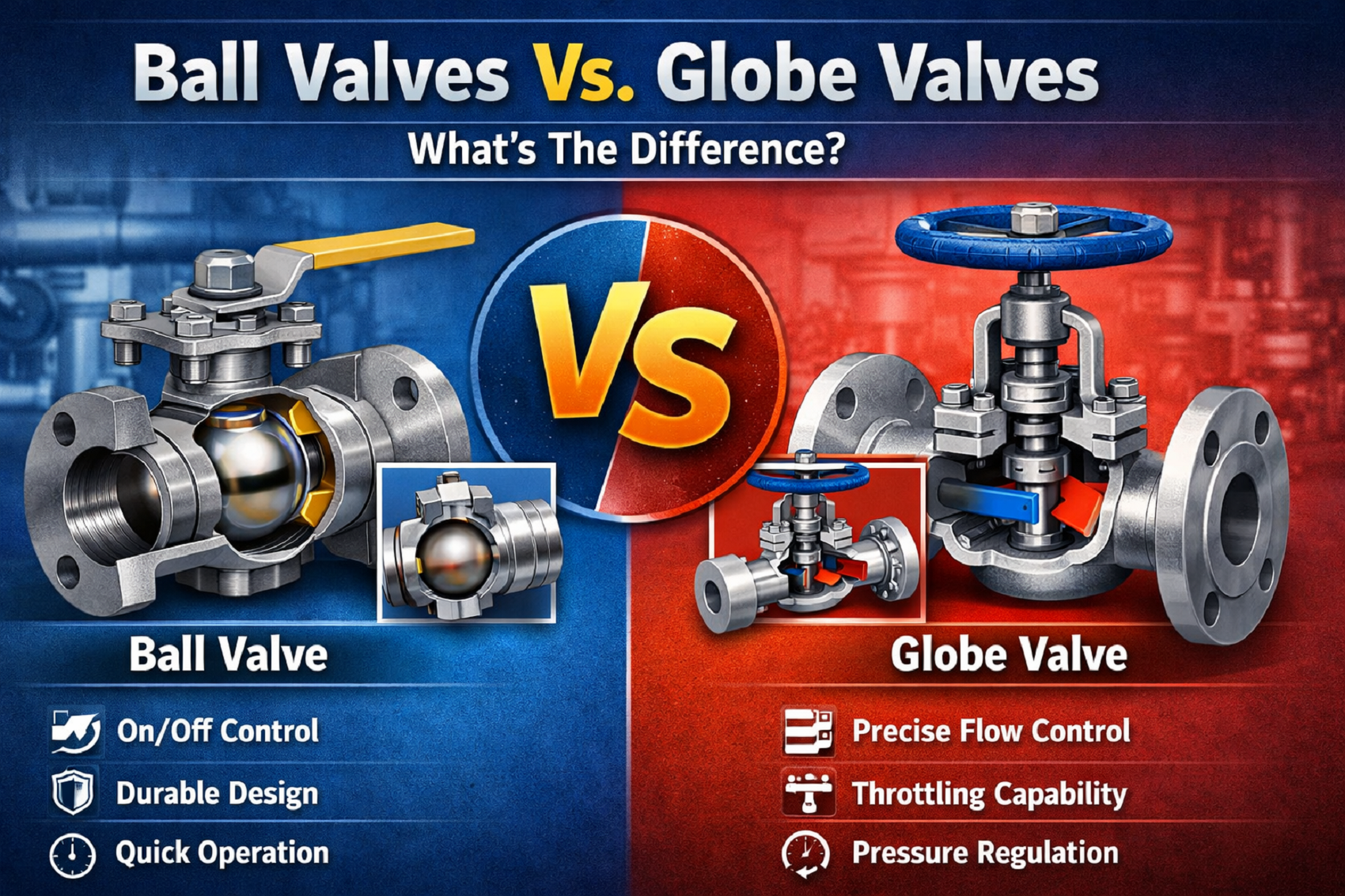

Ball Valves Vs. Globe Valves: What’s The Difference?

Category : Blog | December 24, 2025 | By rzbm19If you work with pipelines, industrial systems, or mechanical services, valves are something you deal with almost every day. Yet we often see confusion when it comes to choosing between a ball valve and a globe valve. Both are widely used across industries in the UAE, from water distribution and HVAC systems to oil and gas, manufacturing, and building services. However, their purpose, working method, and performance are very different.

Understanding Ball Valve?

A ball valve is a quarter-turn valve that uses a spherical ball with a hole through the center to control flow. When the hole aligns with the pipeline, fluid flows freely. When it is turned ninety degrees, the solid part of the ball blocks the flow completely.

Ball valves are mainly designed for on-off control rather than precise flow regulation. Because of their simple internal design, they provide a tight shut-off and minimal pressure drop when fully open.

Understanding Globe Valve?

A globe valve is designed with a movable disc or plug that presses against a stationary seat to control flow. Unlike ball valves, globe valves require multiple turns of the handwheel to open or close.

The internal flow path inside a globe valve changes direction, which allows for better throttling and flow control. This makes globe valves ideal for applications where you need to regulate flow rather than simply stop or start it.

In many industrial and commercial setups across the UAE, globe valves are preferred for systems that require frequent adjustments and controlled flow rates.

How Each Valve Works

Understanding how each valve works internally helps you choose the right one.

A ball valve works by rotating the ball inside the valve body. The flow path is straight when open, which means less friction and lower pressure loss. Because it only needs a quarter turn, the operation is fast and simple, whether manual or automated.

A globe valve works by lifting or lowering the disc using a threaded stem. As the disc moves closer to or farther from the seat, it gradually increases or decreases flow. This design allows precise control but also creates a higher pressure drop due to the change in flow direction.

Key Differences Between Ball Valves And Globe Valves

Control Flow

Ball valves are best for isolation. They are either fully open or fully closed. While partial opening is possible, it is not recommended for throttling because it can damage the ball and seats over time.

Globe valves excel at throttling and regulation. They are designed to operate in partially open positions without causing internal damage.

Operation

Ball valves are faster and easier to use. Globe valves require more turns and more effort but offer better control.

Pressure drop is another major difference. Ball valves have minimal pressure loss when open. Globe valves have higher pressure drop due to their internal design.

When To Use A Ball Valve

Choose a ball valve when your priority is a reliable, long-lasting seal for:

- Shutting off fuel lines or the water supply.

- Isolation points in HVAC systems for our demanding UAE climate.

- Process lines where full, unobstructed flow is needed.

- Any application where quick operation in an emergency is crucial.

When To Use A Globe Valve

Choose a globe valve when you need precise regulation:

- Adjusting cooling water flow to a heat exchanger.

- Controlling steam flow in a heating system.

- Any pipeline where you need to accurately manage pressure or flow rate as part of the process.

- Feedwater systems in boilers.

Advantages And Disadvantages Of Both Valves

Ball valves offer several advantages. They provide excellent sealing, require minimal maintenance, and operate quickly. Their compact design also makes them easy to install in tight spaces.

However, ball valves are not suitable for throttling. Using them in partially open positions can cause erosion of the seats and reduce valve life.

Globe valves offer excellent control and stable operation under varying flow conditions. They are reliable for regulating flow and handling frequent adjustments.

On the downside, globe valves are bulkier, create a higher pressure drop, and usually cost more than ball valves of similar size. They also require more time to operate fully open or closed.

Which Valve Is Right For Your Application?

Choosing between a ball valve and a globe valve depends on what your system needs most.

If your goal is simple on-off control with minimal pressure loss, a ball valve is the smarter option.

If your system demands accurate flow control and frequent adjustments, a globe valve will serve you better.

At RZBM, we always look at factors like operating pressure, temperature, media type, automation requirements, and long-term maintenance before recommending a valve. There is no one-size-fits-all answer, and selecting the wrong valve can lead to inefficiency, increased downtime, and unnecessary costs.

That is why working with a knowledgeable supplier matters.

Conclusion

Ball valves and globe valves may seem similar at first glance, but they are designed for very different purposes. Understanding these differences helps you make informed decisions that improve system performance and reliability.